Well, in my haste I made a little boo boo. I know, I know! I have

NEVER said that before! When the U-bolts came off the nicely welded shock attachments had to be removed as well. Unfortunately it is a tapered shaft that runs from the extender arm into the shock absorber. As such I had to remove the shock from the bus frame, take the whole contraption (shock-extender arm-U-bolt) down to the work shop, put it in a vise add a little heat and 'POP' the shaft out of the shock. Well I was a little worried to hit the end of the shaft in fear that when I did I would mushroom the end and damage the threads. So I decided to leave the nut on the end and 'TAP' the nut.

Unfortunately, because I had already done this and

knew what I was doing, I was a little too....shall we say....eager. My

tap was more like a rushed "WHACK!" and two things happened. First the nut split and when it did it seemingly buggered the shaft threads near the end.

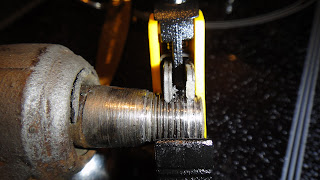

I had that fight or flight kinda feeling....you know when your heart leaps up into your throat and you just want to throttle someone....oh wait that's just how Michelle feels when I am obsessing about the bus.... Seriously I could literally feel my blood pressure raise, my head got warm and my hands were tingling. I know this could be bad. You can't exactly just run down to NAPA and get a new one of these suckers.(truth be known the above photo was taken after the first path of the miracle fix)

So cooler heads prevail, aka I was disgusted with myself and aborted the mission. Jeff and I tidied up and put everything away..... and I slept on it.

In the morning I googled 'thread restorer'. (By the way when did it become a verb in popular culture anyway?) I thought best case scenario I could find some kind of super specialty part in south America or something and bring it in in hopes that it could solve my stupidity. But guess what....ya you know it...your favorite place, and mine. The magical world of Lee Valley Tools. A $25 universal thread restorer!

As simple as it looks, same action as a pipe cutter. Clamp it on, tighten it up, spin it around...done!

After a few passes and a new 1/2" fine thread bolt from the bolt warehouse. We are back in business in under 24 hours!