I will prewarn those of you who want bus and bus only...this is thin on bus but thick on love.

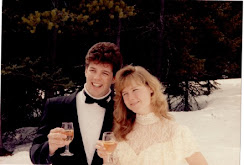

As a young, newly married, man I remember doing some work with my Dad at my parents place in Manitoba. I cant remember the specifics of it all but, suffice it to say, that I was the beneficiary of his time and generosity. I specifically remember feeling a little sheepish that I was an independent married man and yet I needed help to get where I needed to go. Turning to him, I humbly said, 'thank you Dad, I couldn't have done this with out your help, and I will pay you back!' My Dad, being my Dad a man who chose his words wisely, said 'You're welcome, being able to spend time with you is what makes me happy, I'm just glad that you still want my help. And if you want to pay me back, then offering the same opportunity to your kids is all the payment I will ever need.'

I think of that moment all the time, especially now as my kids are growing up and becoming more and more independent. But whenever they call me up (snap me is more likely) and say "hey Dad! can you help me with...." I've already dropped my personal project and mentally said 'Sure!' before they can finish their question.

Anna called me up the other day and said in her gentle way, "if you want to come see our new place (moving in with two other Bragg Creek girls in Calgary) we are getting the keys after work." I wouldn't miss it for the world.

Seeing the excitement of the girls gave me joy.....and the energy to move their stuff into the new pad!

Jeff was not far behind, his request actually happened months ago. He asked me if I would help him build custom bumpers for his truck. The following months of talking about it, planning it, and researching design ideas is what got Jeff through some of the burn out times in first year engineering! Being that I can weld, but not a '

welder', and because I don't have all the equipment, experience or know how to do any of this..... I said "Sure!". I can buy tools, but I can't buy time with the kids.

The last number of days Jeff and I have been making noise in the garage as we design our way through the project......and I know Poppi is smiling down on us right now watching it all happen.

Special kudos to my buddy Doug, who was very generous to lend us his BRAND NEW, STILL IN THE BOX plasma cutter for the project....let me tell you kids, this sucker is a game changer. If you do metal work and never used one its equivalent to the difference between seeing a picture of a car vs driving the car. This is fast and clean and easy to make shaped cuts.....really....I think I'm in love.

And now for a touch of bus. Further on the ladder inner support saga, by turning my horizontal support 90 degrees(now running parallel to the path of the door hinge mechanism) and making one per side, I was able to unobtrusively achieve what I set out to do! Now just the bottom supports........(cue the theme from the 1907's movie Jaws)